In an industrial environment where precision, speed, and connectivity have become essential criteria, the EL8 series stands out as an essential solution for automation professionals. Designed to deliver high performance, simplified integration, and maximum safety, this range of servo drives distributed by SOPROLEC represents a new era in motion control.

A Major Evolution in Motion Control

Industrial needs are evolving toward greater productivity, flexibility, and safety. It is in this context that the EL8 series was developed. Adapted to the most demanding applications such as robotics, CNC machines, packaging, multi-axis positioning, or pick & place systems, it combines advanced servo technology with a compact, communicative, and scalable design. The EL8 series provides integrators, machine builders, and engineering firms with a high-performance, modular, and durable tool.

Performance Serving Precision

The core of the EL8 drive is based on a high-speed vector control architecture utilizing sinusoidal SVPWM modulation. This technology ensures an ultra-fast dynamic response while maintaining perfect stability and precise control of torque and speed, even under variable load conditions. Thanks to its inertia compensation algorithms and adaptive filtering, the drive guarantees micrometric positioning accuracy, ideal for applications that require fine and consistent motion control.

The intelligent servo of the EL8 integrates a dynamic auto-tuning function that greatly simplifies commissioning. In just a few seconds, the system automatically adjusts the PID gains according to the load and the mechanical rigidity of the installation. Coupled with the Motion Studio software, it allows real-time visualization of speed, torque, and position curves, thus facilitating diagnostics and performance optimization. This intelligent auto-tuning system significantly reduces setup time while ensuring motion stability without oscillations or unwanted vibrations.

Advanced Servo Features

The EL8 series also stands out thanks to a series of smart servo functions that improve system precision, speed, and safety.

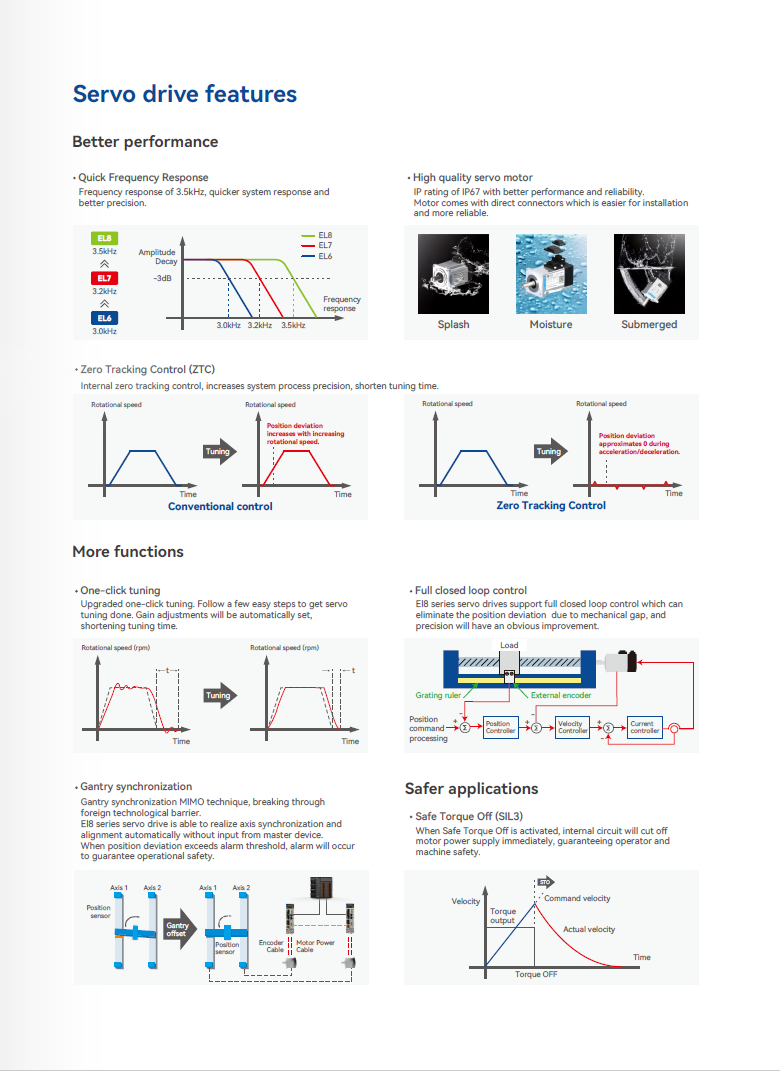

Among these innovations are the fast frequency response (up to 3.5 kHz), ensuring immediate reaction to load variations, the Zero Tracking Control (ZTC), which eliminates position deviations during acceleration, and the one-click tuning function that simplifies and speeds up servo gain adjustments.

The drive also features full closed-loop control, eliminating errors caused by mechanical play or backlash, ensuring unmatched positioning accuracy. The Gantry Synchronization function allows synchronization of multiple axes with extreme precision, ideal for multi-axis machines or gantry handling systems.

See the image below for more details on the EL8 advanced servo features:

Connectivity and Universal Communication

The EL8 drive integrates easily into all types of industrial architectures thanks to its compatibility with the main communication protocols. It supports EtherCAT for ultra-fast real-time control, allowing synchronization of up to 128 axes. It is also compatible with CANopen, known for its simple integration and reliability, as well as Modbus RTU, which ensures universal communication via RS-485, ideal for direct connection to most PLCs on the market. This communication openness makes the EL8 series perfectly suited for both new installations and modernization projects.

In addition to bus communication, the drive offers a complete I/O interface including up to 16 configurable logic signals. These include “Home”, “Limit+”, “Limit-”, “Servo ON”, and “Emergency Stop” inputs, as well as “Servo Ready”, “Alarm”, “In-Position”, and “Brake Control” outputs. PNP/NPN compatibility and extremely short response times (less than 1 microsecond) ensure optimal reactivity in high-speed applications.

Motor Compatibility and Application Flexibility

The EL8 series is fully compatible with ELM Series servo motors, covering a wide power range from 200 W to 7.5 kW. These motors are available in standard, high-speed, or high-torque versions depending on application needs. Their 23-bit multi-turn absolute encoder provides exceptional resolution, ensuring precise positioning without data loss even after a power cut. This compatibility allows each drive/motor combination to be tailored to the application, whether for high-speed movement, torque control, or fine positioning.

The drive supports several control modes: Position mode for indexing or cutting tasks, Speed mode for continuous drives such as conveyors or winding systems, and Torque mode for applications requiring force control, such as screwing or pressing. An automatic homing mode completes these functions to simplify the axis reference cycle.

Integrated Safety and Industrial Reliability

Safety is at the heart of the EL8 drive’s design. All models integrate the STO (Safe Torque Off) function certified SIL3, allowing instantaneous deactivation of motor torque without cutting the drive’s power supply. This function provides effective protection for both operators and machines, in compliance with European industrial safety standards.

At the same time, the drive incorporates a complete set of protections against overvoltage, undervoltage, overheating, overloads, short circuits, phase loss, encoder errors, and overspeed. An internal logging system (“Black Box”) records events and anomalies, simplifying diagnostics and preventive maintenance. This embedded intelligence increases system reliability while reducing downtime.

Intuitive Operation and Simplified Maintenance

One of the key strengths of the EL8 is its ease of use. Its front panel includes an 8-segment LED display and five ergonomic navigation buttons, making configuration straightforward. The integrated USB Type-C port allows quick communication with a PC via Motion Studio, without the need for main power. Users can easily configure, save, and restore parameters.

The intelligent cooling fan system automatically adjusts its speed based on internal temperature, reducing noise and energy consumption. This compact design, combined with excellent thermal management, ensures stable operation and extends equipment lifespan.

Applications Across All Industrial Sectors

Thanks to its flexibility and performance, the EL8 series finds its place in numerous industries. It is used in packaging and labeling machines, automated production lines, CNC machines, industrial robots, as well as dosing, pressing, and filling systems. Wherever precision, speed, and reliability are required, the EL8 provides a robust and high-performance solution.

Why Choose the EL8 Series?

The EL8 drive stands out for its concrete advantages: exceptional servo performance, multi-protocol compatibility (EtherCAT, CANopen, Modbus RTU), integrated safety functions (STO SIL3), fast commissioning with auto-tuning, intuitive interface, and extended motor compatibility. Its modern design and built-in intelligence make it an ideal choice for manufacturers seeking to combine performance, simplicity, and safety.

Conclusion

The EL8 series perfectly embodies SOPROLEC’s philosophy: providing industrial customers with innovative, reliable, and connected automation solutions. Thanks to its advanced servo technology, integrated safety, and universal compatibility, the EL8 drive stands as a key partner for all machines where performance, precision, and safety are priorities. With SOPROLEC, you benefit from complete technical support to integrate the EL8 series into your projects and optimize your automation systems with confidence and efficiency.